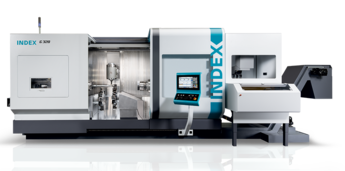

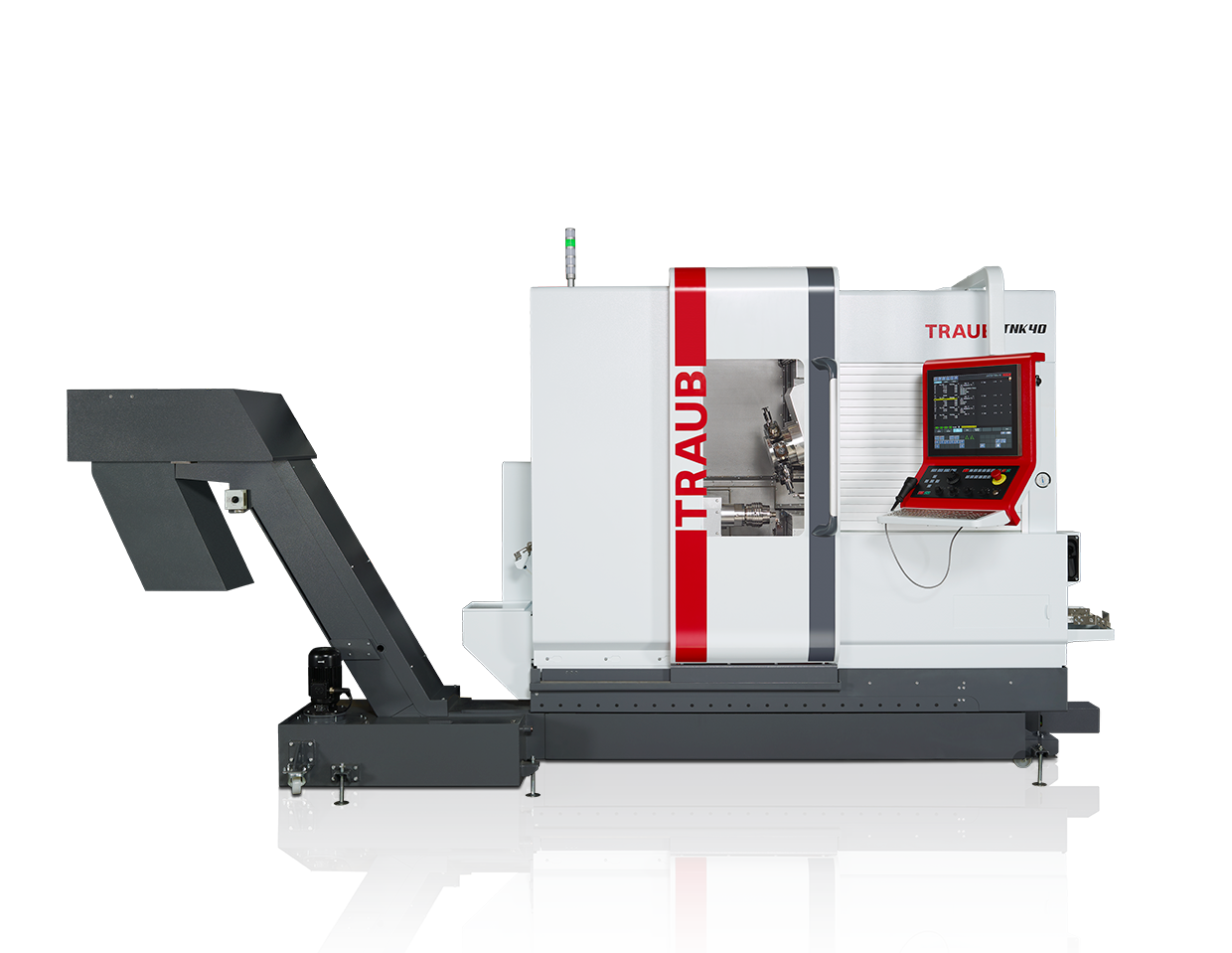

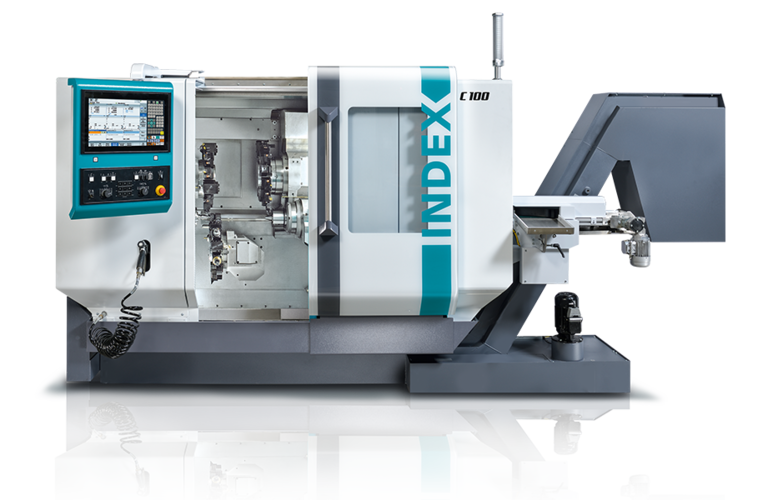

Production turning machine for robust and cost-effective machining

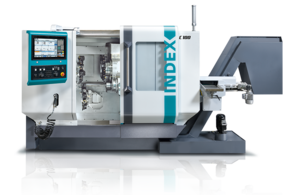

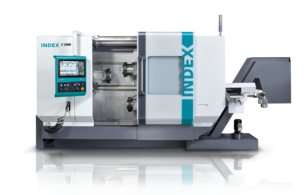

Machine highlights - TRAUB TNK40

Your benefits

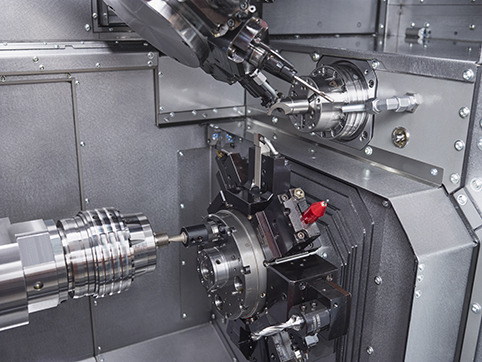

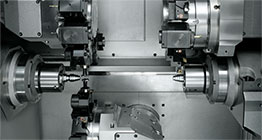

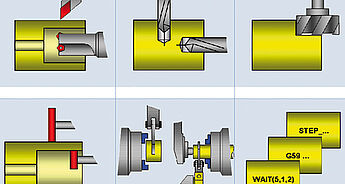

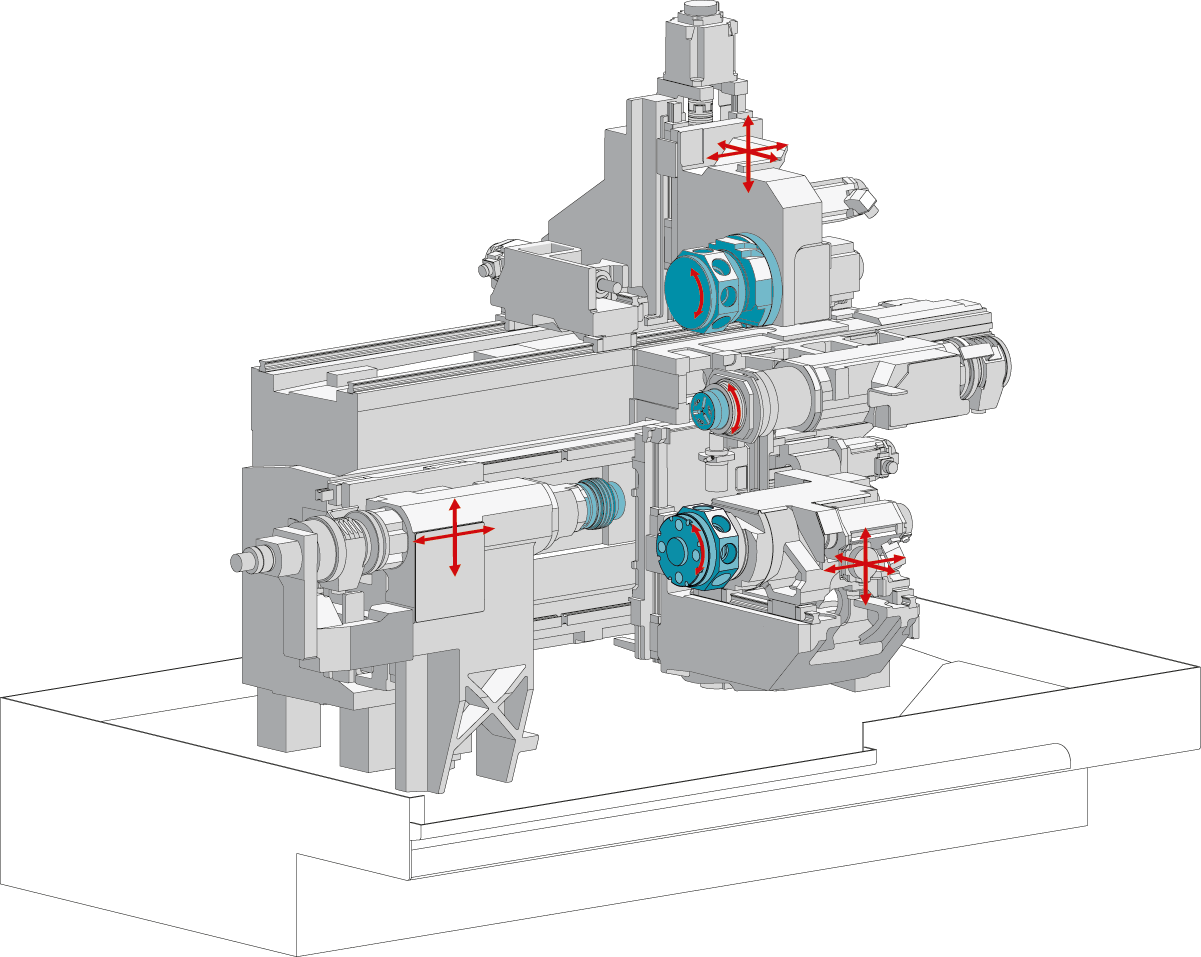

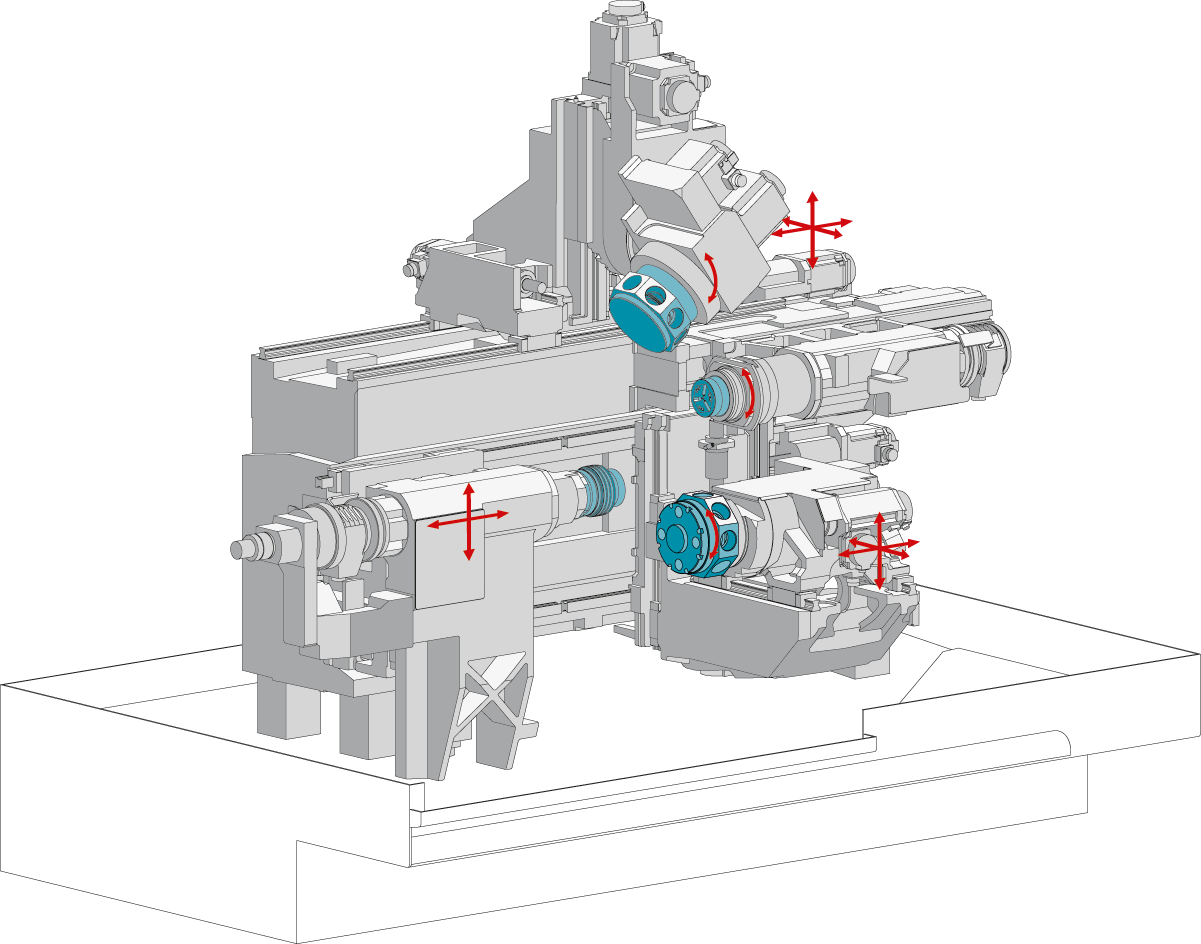

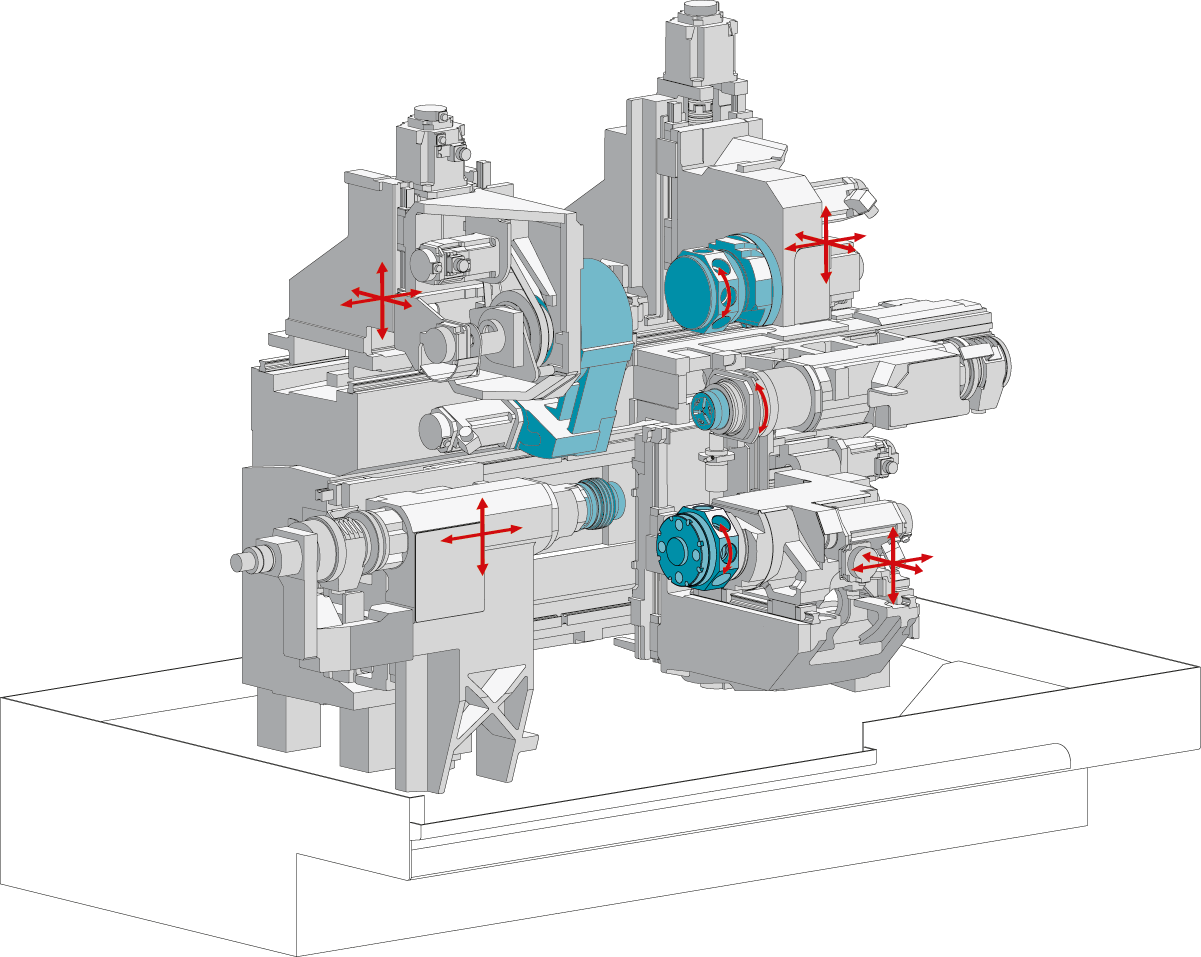

Two identical work spindles, two tool turrets (each with X, Z, Y axes)

Spindle clearance up to Ø 40 mm

Robust fixed headstock design

Stable compact-shank tool holders for precise milling

Optional single drives available for tool stations

Up to three tool carriers and one back working unit, all with Y axis

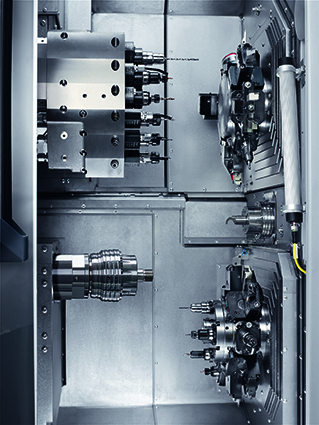

Simultaneous machining with two, three or four tools

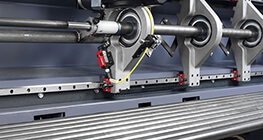

Large tool pool for setup-friendly production

Short tool change times

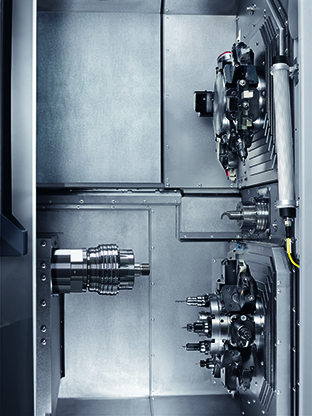

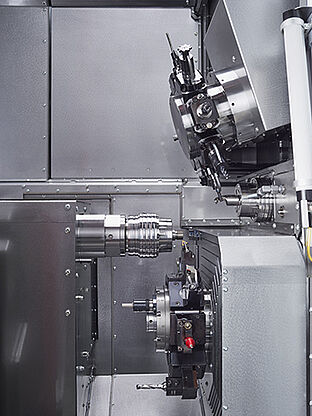

Generously dimensioned work area designed for process reliability

Flexible hydraulic hollow clamping system (main & counter spindle)

Machine concept TRAUB TNK40

The TRAUB TNK40 has two identical work spindles and two tool turrets, each with X, Z, and Y axes. It can also be equipped with a front and back working unit. The upper tool turret can be equipped with an optional B axis.

This production turning machine combines the productivity of a very high-performance turning machine with the precision and efficiency needed to machine complex workpieces with ease.

With its compact footprint, the work area of this production turning machine—which is unique in its class—ensures a very high power density for cost-effective production. In addition, the vertical work area concept provides optimum process reliability combined with minimal setup effort.

The work area concept allows simultaneous and productive machining with two tool turrets and a front and back working unit.

TRAUB TNK40 in focus